07-01-2019

Polyurethane rubber or plastic: terms are often mixed up

We see or hear it quite often: a question for polyurethane rubber or polyurethane plastic. Two different terms are then linked together in the enquiry. Mixed up, as if the two words together form an expression. But that is not the case. Because polyurethane is not a plastic. And actually no rubber either. We would like to tell you more about it in this Ridderflex knowledge blog.

Polyurethane rubber or polyurethane plastic

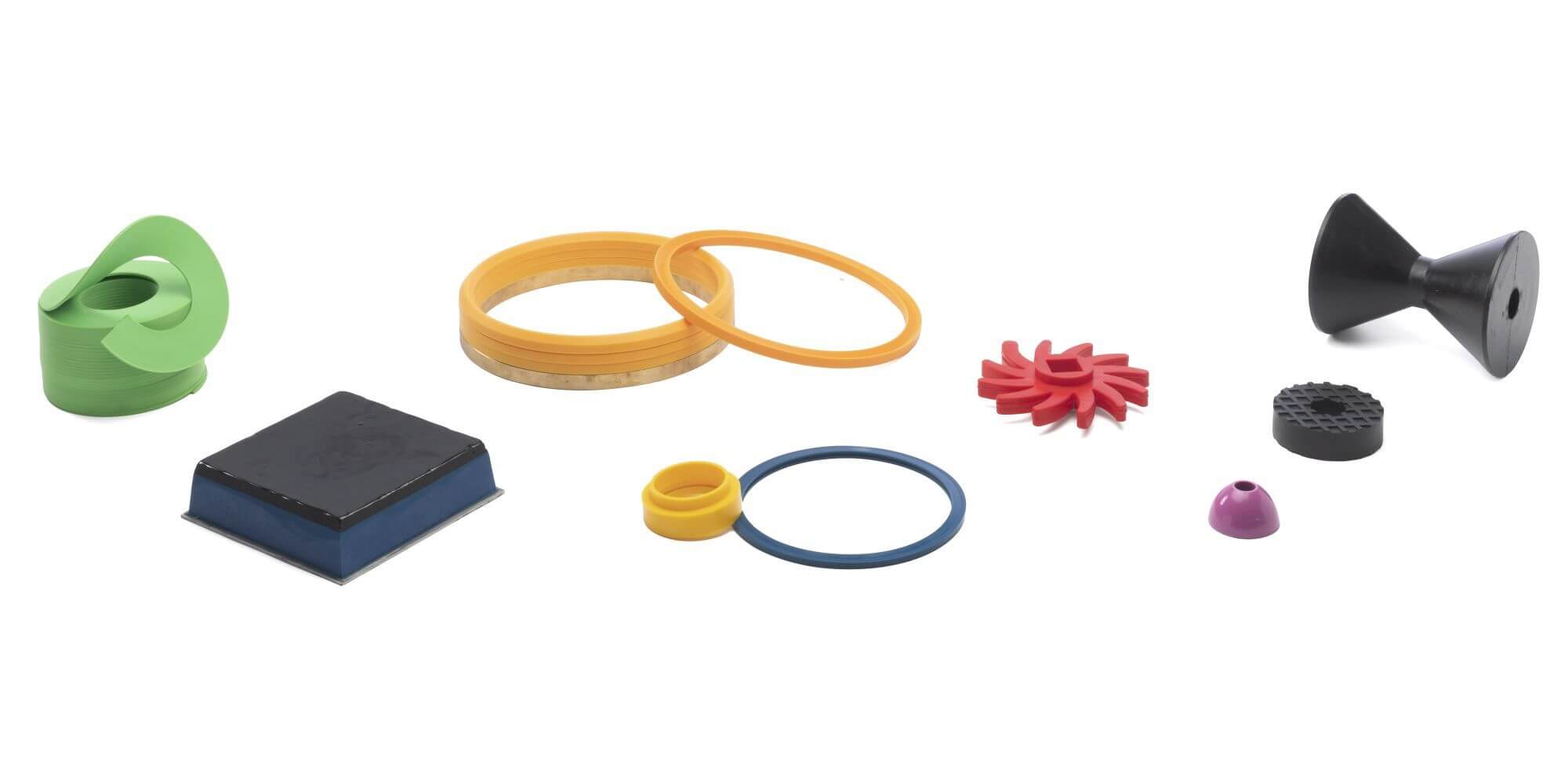

Why are the terms polyurethane rubber and polyurethane plastic so often used? Polyurethane (or ‘PU’) is so versatile and flexible: it simply is confusing. The material often looks and feels like rubber. Or like plastic. Certainly black, gray or white products can put you on the wrong track. Therefore it is not surprising that people often ask for polyurethane rubber or polyurethane plastic.

What is polyurethane?

But what is PU, then? Professor Dr. Otto Bayer invented this special material in 1937. It is a copolymer based on polyols and isocyonates. A copolymer? But a plastic is a copolymer as well, isn’t it? – No. Often it is not. Usually it is a polymer. But let’s keep it simple.

Polyurethane is actually not a (natural) rubber nor a plastic, but is something ‘in between’. It has the strength of plastic and the elasticity of rubber. The material can be mixed in different proportions (‘systems’). That makes a huge variety of properties possible. Think of hard, soft, flexible, tough, light materials and different colours. Almost anything is possible

Polyurethane compared to rubber and plastics

Most variation in polyurethane is visible and tangible. Visible in the endless colour options. Tangible in different hardnesses. Polyurethane products can be made in 15 Shore A to 95 Shore A and in 40 Shore D to 77 Shore D. That is not possible with rubber. And neither with plastic. If you want a soft rubber product, you can choose a cellular rubber or foam rubber. A hard rubber product? – Pick a 70 or 80 shore quality. If you choose a product in the plastic POM, than that product has only one hardness. But, if we still would want to compare PU with rubber and plastic, then we would have to study the full diversity of the material’s hardness. If we put this in a table, it turns out that comparison remains difficult. Because polyurethane is so much more versatile.

Term polyurethane rubber is not correct

Calling PU ‘polyurethane rubber’ or ‘polyurethane plastic’ is confusing. And we actually would compromise PU. We even dare to say that no other material in our product range is so flexible and versatile. And that polyurethane offers many advantages over other materials in the industry. The advantages of PU versus other materials in the industry are:

PU versus Metals

- Absorbing sounds and noises instead of reverberating it

- Corrosion resistant

- Cheaper toolings for production

- Lighter in weight

PU versus Rubber

- Available in different colours

- Cheaper toolings for production

- Extremely good performance in the 80A to 95A durometer range

- Easier production of complicated parts

- Better wear resistance

- No aging problems, such as drought cracks

PU versus Plastics

- Elastomeric memory (goes back in its original shape)

- Easier production of complicated parts

- High wear resistance

- Retains high impact resistance, even at high hardnesses

- Not brittle

Products of polyurethane

The possibilities of polyurethane are almost infinite. Without exaggeration: polyurethane products make our lives easier. These products are part of our daily lives. Think of car parts, shoe soles, paint, floors and wheels. Polyurethane products can also be the solution for many technical problems.

Do you want to see what products we can make in polyurethane? Then especially have a look at our polyurethane products.