Polyurethane coating and lining

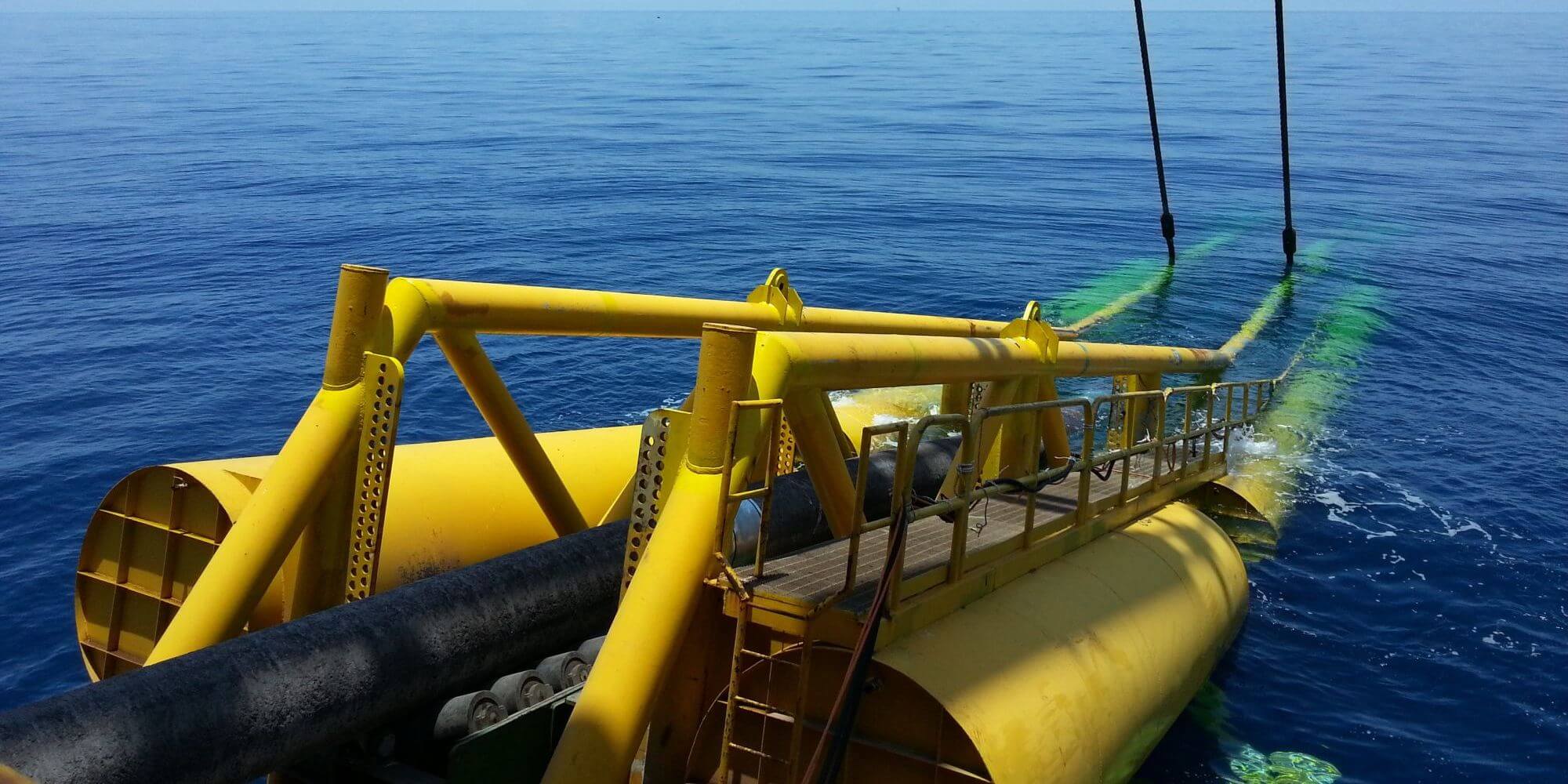

Ridderflex can coat products and cover rollers with polyurethane. Polyurethane is an excellent protective layer for various materials.

Wheels, rollers, rolls, sleeves and other parts can be covered with polyurethane to make them more wear resistant.

Polyurethane roller covering

There are various methods for applying polyurethane to a product. Spraying is used to apply a thin coating layer. The roller covering technology we use offers more possibilities as it enables better adjustment to the specific application of the product. Another advantage of our roller covering technology over spraying is that the polyurethane is cast onto the product, creating an end result with a greater wall thickness.

Polyurethane coating

When using polyurethane to coat a product, we apply one or more layers of polyurethane to a Mother Mould. We apply the polyurethane layer to the outside, as a result of which the shape may be less exact there.

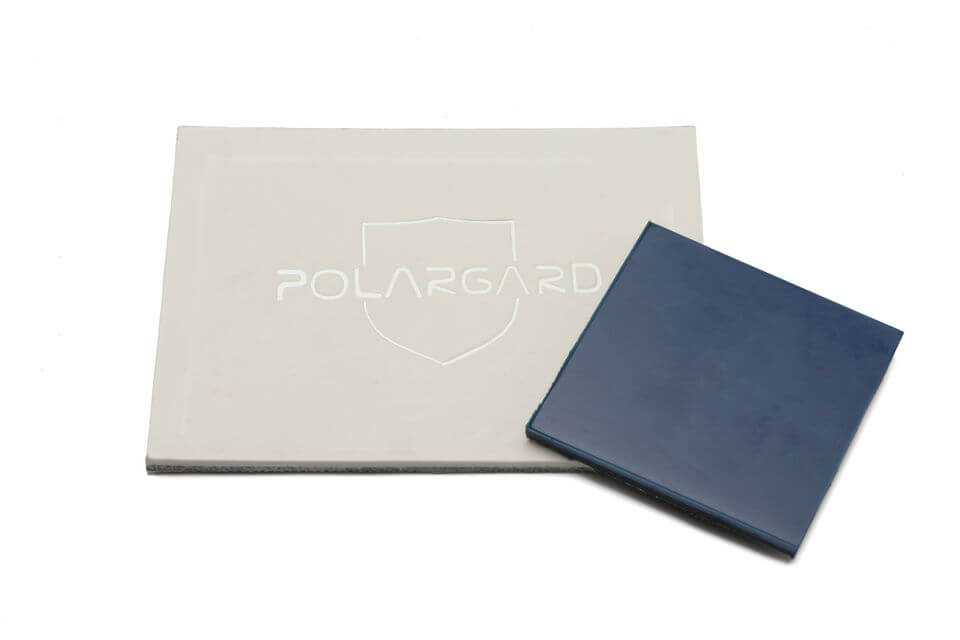

Polargard®: super polyurethane lining product

In 2012, Ridderflex developed a new and unique product which we call Polargard®. This is a hard-wearing polyurethane sheeting material with a backing with an open structure, enabling the Polargard® sheeting to be glued to sheet steel products like vibrating hoppers and chutes. And besides this Polargard® Canvas variety, we also offer Polargard® Steel with a steel inlay. This sheeting material can be attached mechanically.

Question? Enquiry?

We excel in the production of custom-made plastic, rubber and polyurethane products.