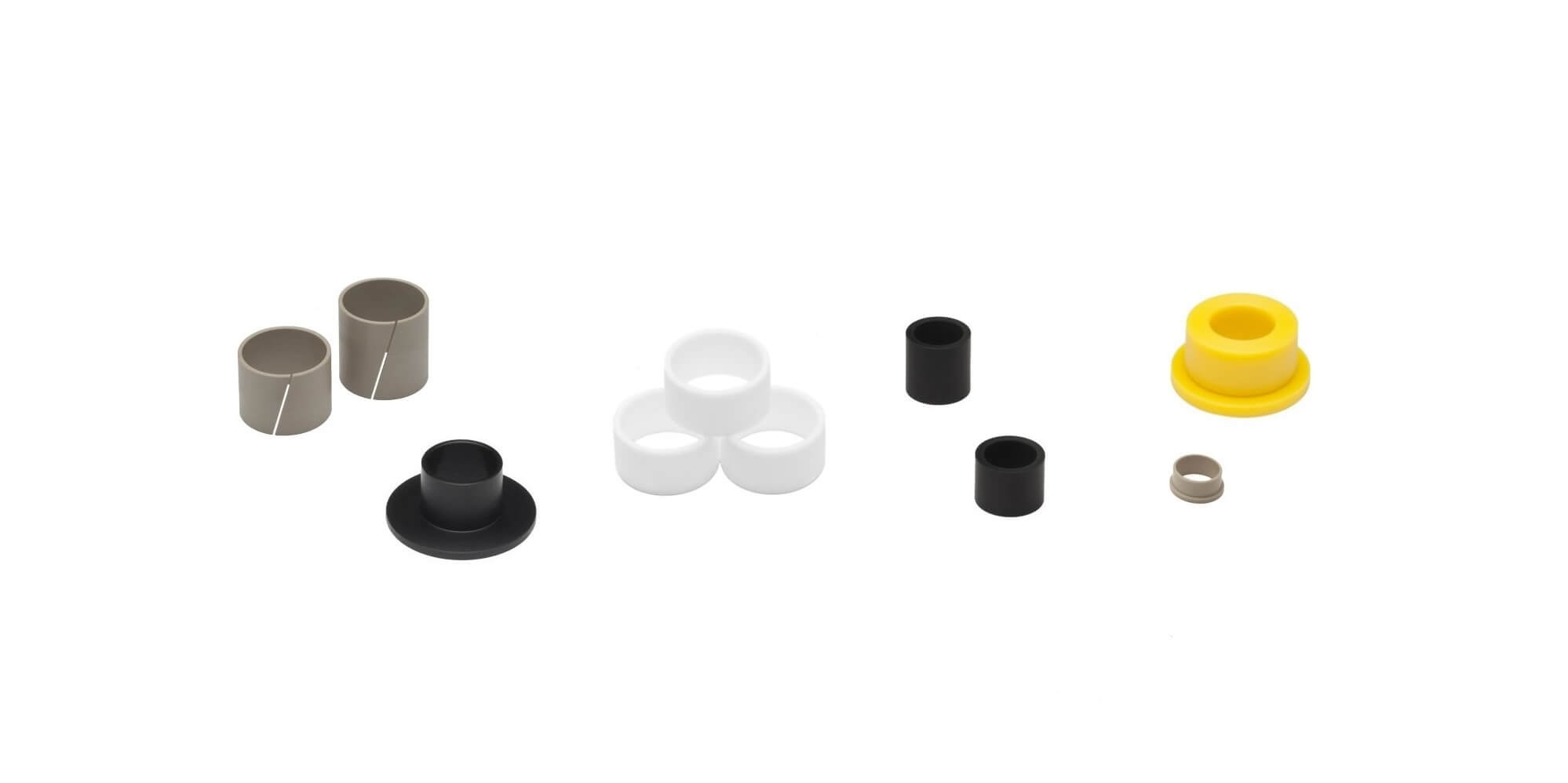

Sliding bearing

A metal sliding bearing always needs a lubricant. Even if the metal has been made self-lubricant. Our plastic sleeve bushing is genuine self-lubricating. – A lubricant is unnecessary – . We can also produce sliding bearings with a good chemical resistance.

Ridderflex is a specialist in machining plastic sleeve bushings. For special applications, but also for conditions where usually metal is applied. In most cases, plastic can be used as an alternative material.

Advantages of a plastic sliding bearing

A plastic sliding bearing:

- has a high load;

- is wear resistant and

- has low friction.

Metal also has a high load and is wear resistant. What are the advantages of choosing a plastic sliding bearing?

- Plastic bearing material is often self-lubricating (with metals this is limited, you always need a lubricant). We even have bearing material in stock, specially developed for extremely dirty environments;

- Our plastic bushes can be produced in a quality with a good chemical resistance;

- Our PTFE bushes are food grade products (FDA).

Custom-made sleeve bushing

Ridderflex has over 25 years of experience in machining plastics. We excel in the production of custom-made sleeve bushings. This can be based on a drawing or model, according to your specifications. We can produce plastic bushings according to your specifications, based on a drawing or model. Depending on the version and dimensions, we produce minimum product series.

PE, POM or Nylon Sliding bearing

PE, POM or Nylon are our standard plastic qualities for sleeve bushings. PE and POM are slightly self-lubricating. When the material requires even better self-lubricating properties, a Nylon sleeve bushing is a better choice.

PTFE, PEEK (bearing grade) or Vesconite ®

In critical applications, such as higher temperatures or extremely dirty or humid conditions, we recommend sliding bearings with high-grade materials. PEEK (bearing grade) or Vesconite ® are the perfect choice for your sleeve bushing. But also PTFE, with its good chemical resistance, is a good material. It can also be used in direct contact with food (FDA).

In the table below we will explain what the key properties of these high-grade materials are. Of course we are happy to advise you about the possibilities.

PTFE

PTFE virgin (PTFE Teflon ®) is physiologically inert and may be used in direct contact with food (FDA). The material excels because of its wide temperature range and good resistance. PTFE virgin has a good chemical resistance. It also has very low friction.

PEEK PVX®

PEEK PVX® is a material specially developed for bearings. It has a very high temperature and pressure resistance. PEEK PVX® has good mechanical properties and a very good chemical resistance. The material also has a very high tensile strength and is creep resistant. Because of the PTFE additive, PEEK PVX® has good sliding properties. Ridderflex often applies the material in parts in critical applications.

PEEK PTFE

PEEK PTFE is also a material specially developed for sliding bearings. The material has good mechanical properties and a very good chemical resistance. It also has a very high pressure and temperature resistance. Because of the PTFE additive, PEEK PTFE has good sliding properties. The material also has a very high tensile strength and is creep resistant.

Arlon ® 1555

Arlon ® 1555 is a PEEK quality with a very high pressure and temperature resistance. The material also has a high tensile strength and is creep resistant. Because of the PTFE additive, the material has good sliding properties. This makes Arlon ® 1555 the ideal bearing grade, especially applied in critical applications.

Vesconite®

Vesconite ® is a ‘wonder material’, specially developed for bearings. Vesconite ® can be applied in extremely dirty, dusty and humid conditions (such as gold and coal mines). The material is developed to rotate without any kind of external lubrication (self-lubricating). Vesconite ® has a long service life. The material has a very high pressure resistance, good wear resistance and low friction. It is also dimensional stable and the material has limited moisture absorption. This makes the material also suitable for applications under water.

Question? Enquiry?

We excel in the production of custom-made plastic, rubber and polyurethane products.