AFM 34 and AFM 30 products

AFM 34 is a non-asbestos gasket sheet built up by synthetic fibers and bound by a NBR elastomer. This gasket sheet is FDA-approved. Therefore, it can be used as a seal in the food industry. AFM 30 is a non-asbestos high-pressure gasket sheet and may not be used in the food industry.

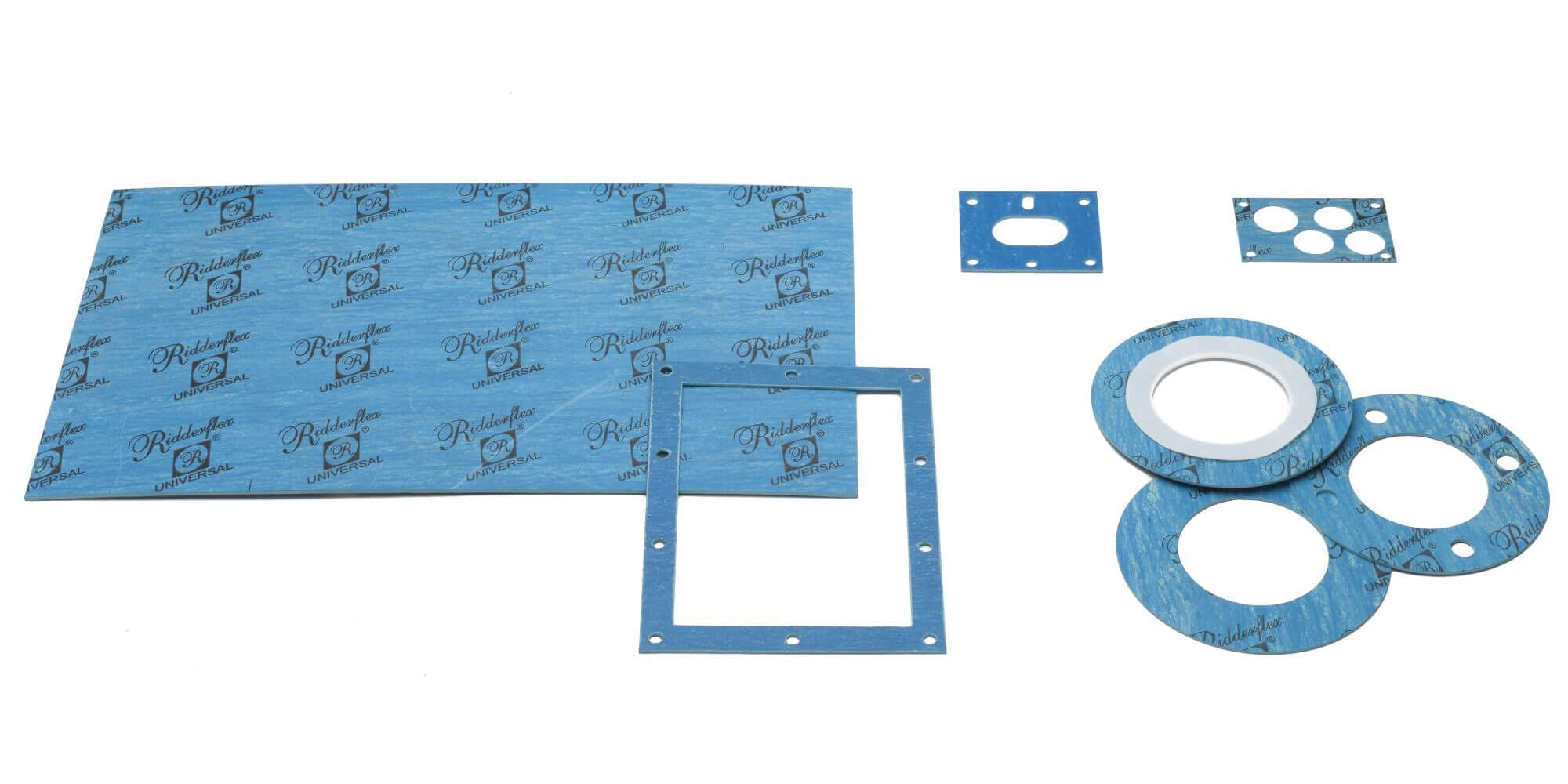

Ridderflex always has a large stock of gasket material. With our die cutting machines or digital cutting and milling machine we cut amongst others custom-made flange gaskets.

Custom-made AFM 34 and AFM 30 products

Ridderflex supplies high-quality flange gaskets according to DIN, ASA and ANSI sizes. We can also produce AFM gaskets and products custom-made. This can be based on a drawing or model.

Various materials

AFM 34 and AFM 30 are different gasket sheeting materials with their own specific properties. In the table below we explain the differences:

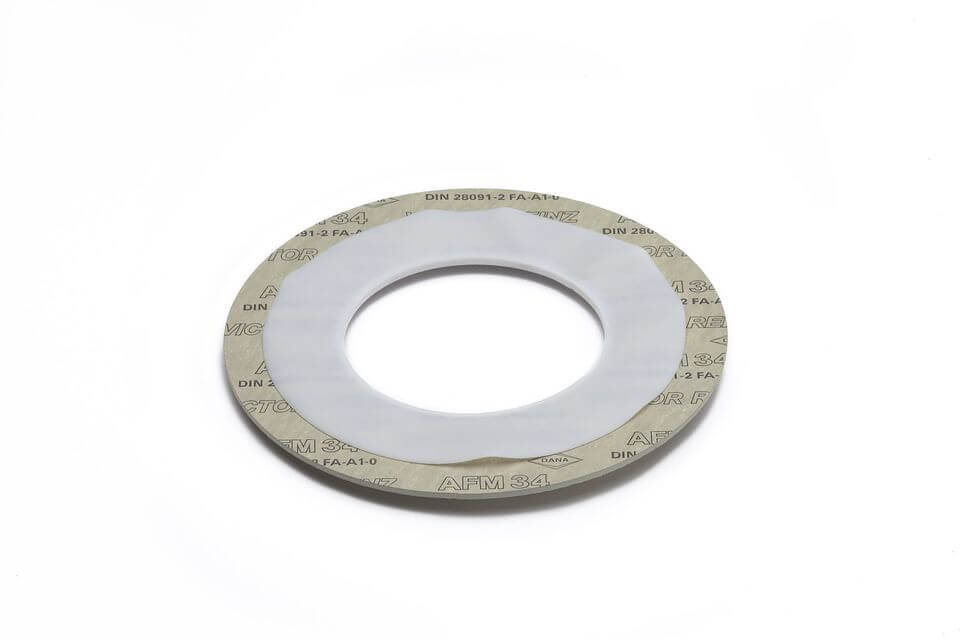

AFM 34

AFM 34 is very good resistant to deformation. The material has a very high tensile strength, a high temperature resistance and is pressure resistant at high temperatures. This gasket material is recommended for the sealing of gases and various liquids. Products made of this gasket material are also applied in industrial devices and plants, piping systems and pumps. This gasket material is FDA approved and can therefore be used in the food industry.

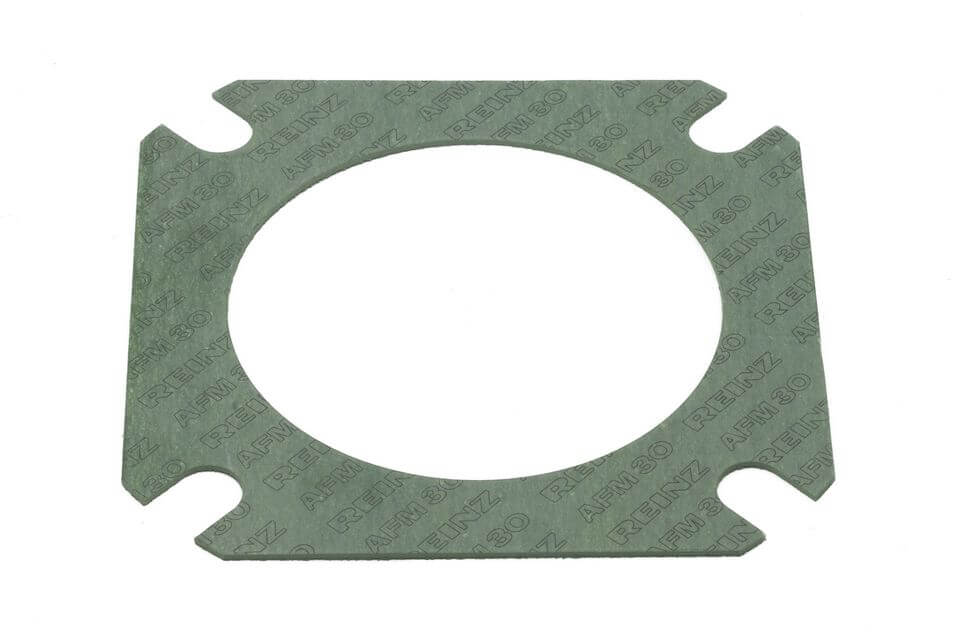

AFM 30

AFM 30 has a high temperature range and is pressure resistant. This gasket sheet is recommended for the sealing of various fluids, such as: transmission oil, coolants and fuels, alkalis and solvents. In addition, the material has a good resistance to steam and is recommended for use at elevated temperatures. Products made out of this gasket material are applied in industrial devices and plants, piping systems and pumps. This product may not be used in the food industry.

Question? Enquiry?

We excel in the production of custom-made plastic, rubber and polyurethane products.