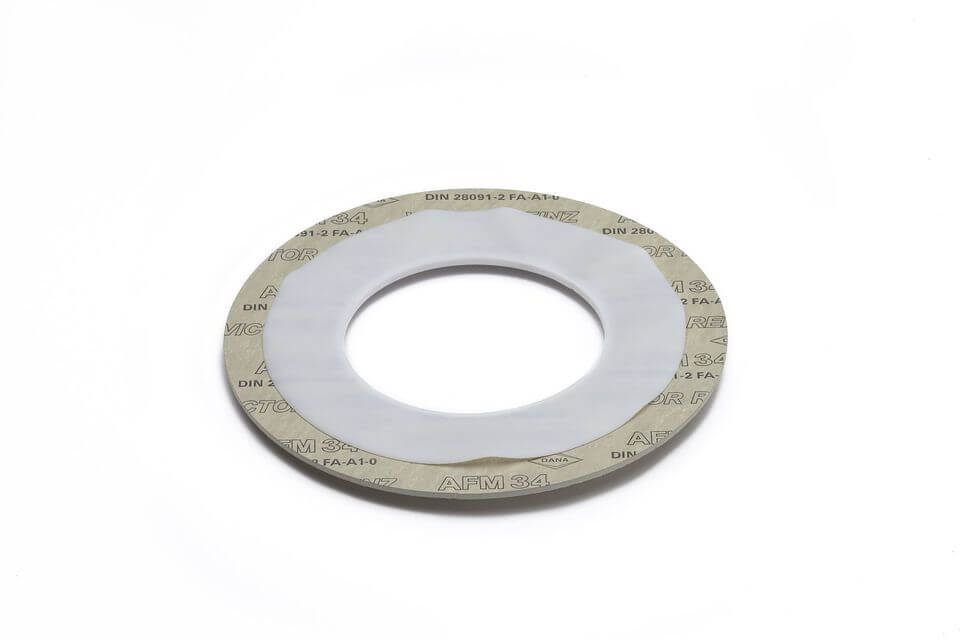

PTFE envelope gasket

A PTFE envelope gasket is a composed gasket. The product consists of an envelope of PTFE with an inlay. The envelope gasket is mainly applied as a flange gasket in applications where a high chemical and high pressure resistance is required.

Properties of a PTFE envelope gasket

Envelope gaskets have the chemical resistance of PTFE, but the strength and resilience of the inlay material. PTFE envelope gaskets combine the benefits of different materials:

- Good chemical resistance.

- Wide temperature range. This depends both on the envelope as the inlay material.

- Good pressure resistance, depending on the choice of the inlay material.

Applications of the PTFE envelope gasket

In a chemical aggressive environment, where pollution of the medium is not allowed, it is complicated to apply a standard gasket. Here PTFE envelope gaskets are applied as flange gaskets. For example, in the (petro) chemical industry and in the process industry.

The envelope gaskets are also ideal for application in the food industry. PTFE is physiologically inert and may be used in direct contact with food (FDA).

Various types

We supply PTFE envelope gaskets in various types, such as:

| U-envelope | For average and high pressures. |

| C-envelope with diffusion stop | Specially designed gasket with a so-called 3 mm thick diffusion stop. |

| Double U-envelope | Suitable for high pressures. A ‘sealed gasket’ with a linear upper side. Is applied in places where the medium may contact the upper side of the seal. |

| Donut envelope | Suitable for high pressures. A ‘sealed gasket’ with a round upper side. Is applied in places where the medium may contact the upper side of the seal. |

| C-envelope | For average and high pressures, but is suitable for a more flexible inlay (for example rubber). |

| Y- or V-envelope | A low cost solution for lower pressures. The inlay material is up to 2 mm thick. |

The thickness of the PTFE envelope can be adapted to the desired thickness of the gasket (inlay).

Inlay material possibilities

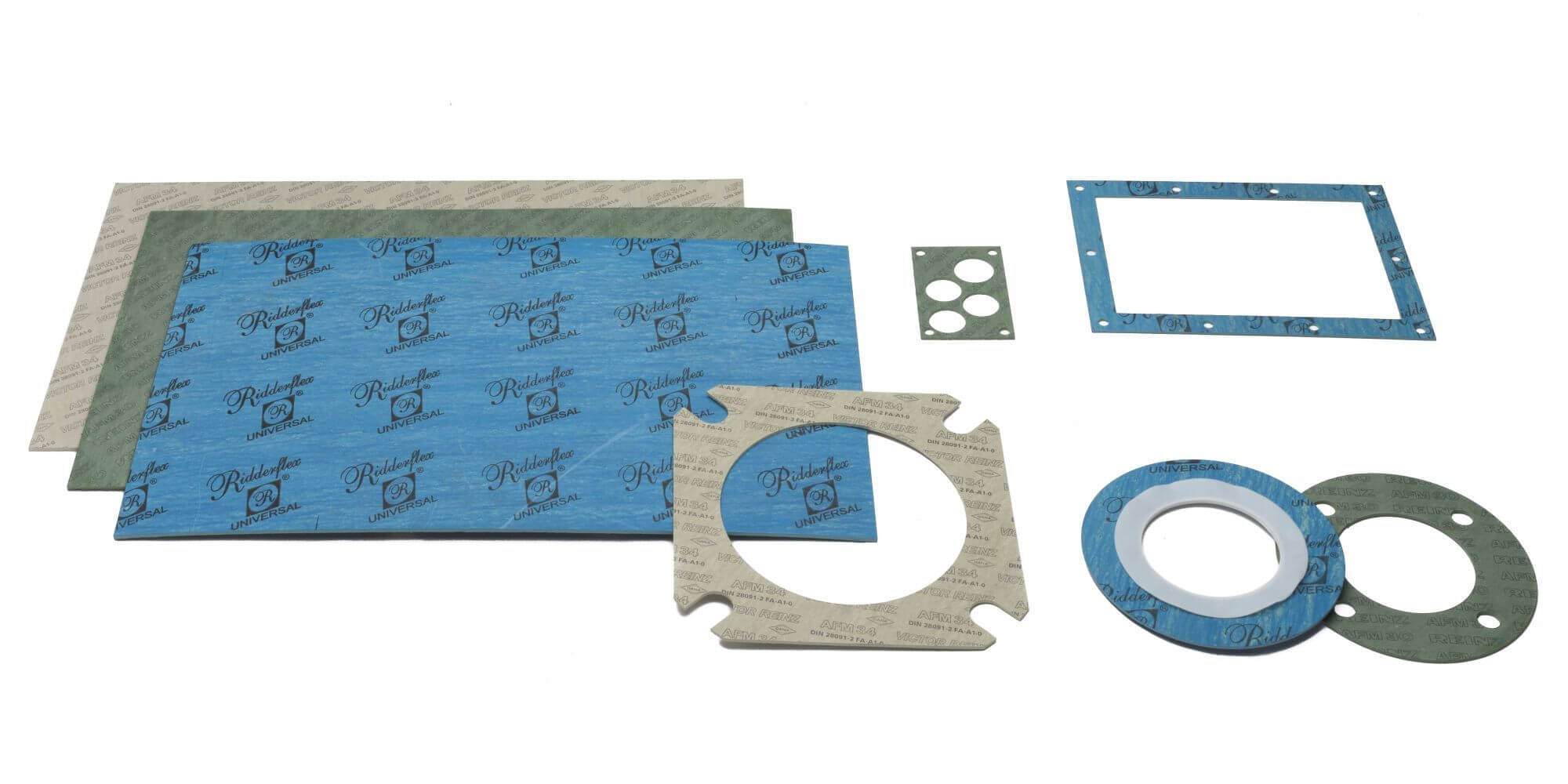

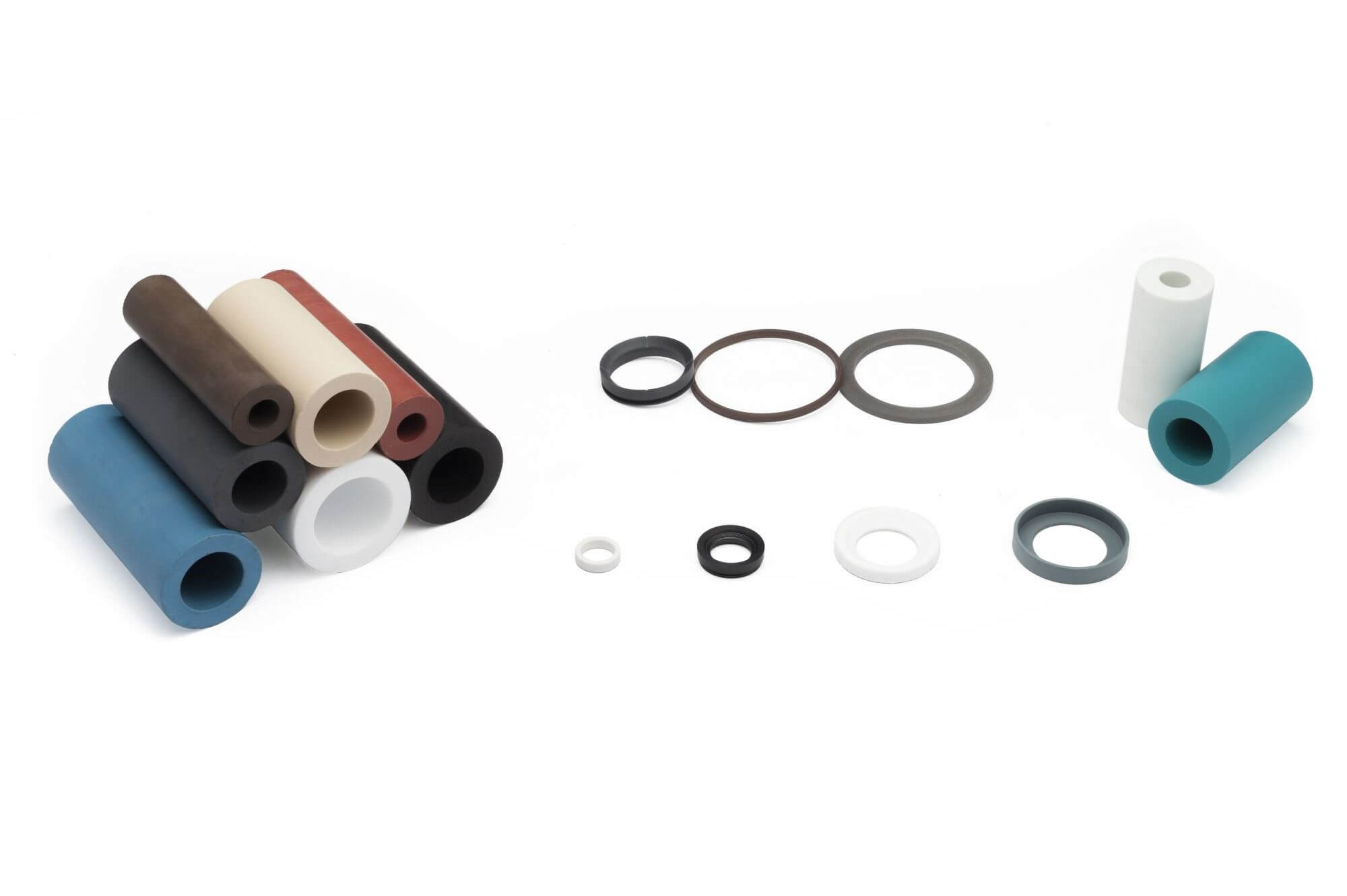

The composition of the PTFE envelope gasket depends on the application. Non-asbestos gasket sheets (high-pressure) and various rubber grades are amongst others applied as inlay material. For applications where a high mechanical strength at elevated temperatures is required, the Graphite special Email is specially designed as gasket material. Our specialists are happy to help you by choosing the right inlay material.

Universal or custom-made envelope gaskets

Ridderflex supplies PTFE envelope gaskets according all standard sizes for flanges: DIN, ASA and ANSI. We can also customise envelope gaskets according to your specifications. This can be based on a drawing or model. We are happy to advise you. Please contact our sales department.

Question? Enquiry?

We excel in the production of custom-made plastic, rubber and polyurethane products.