Water jet cutting

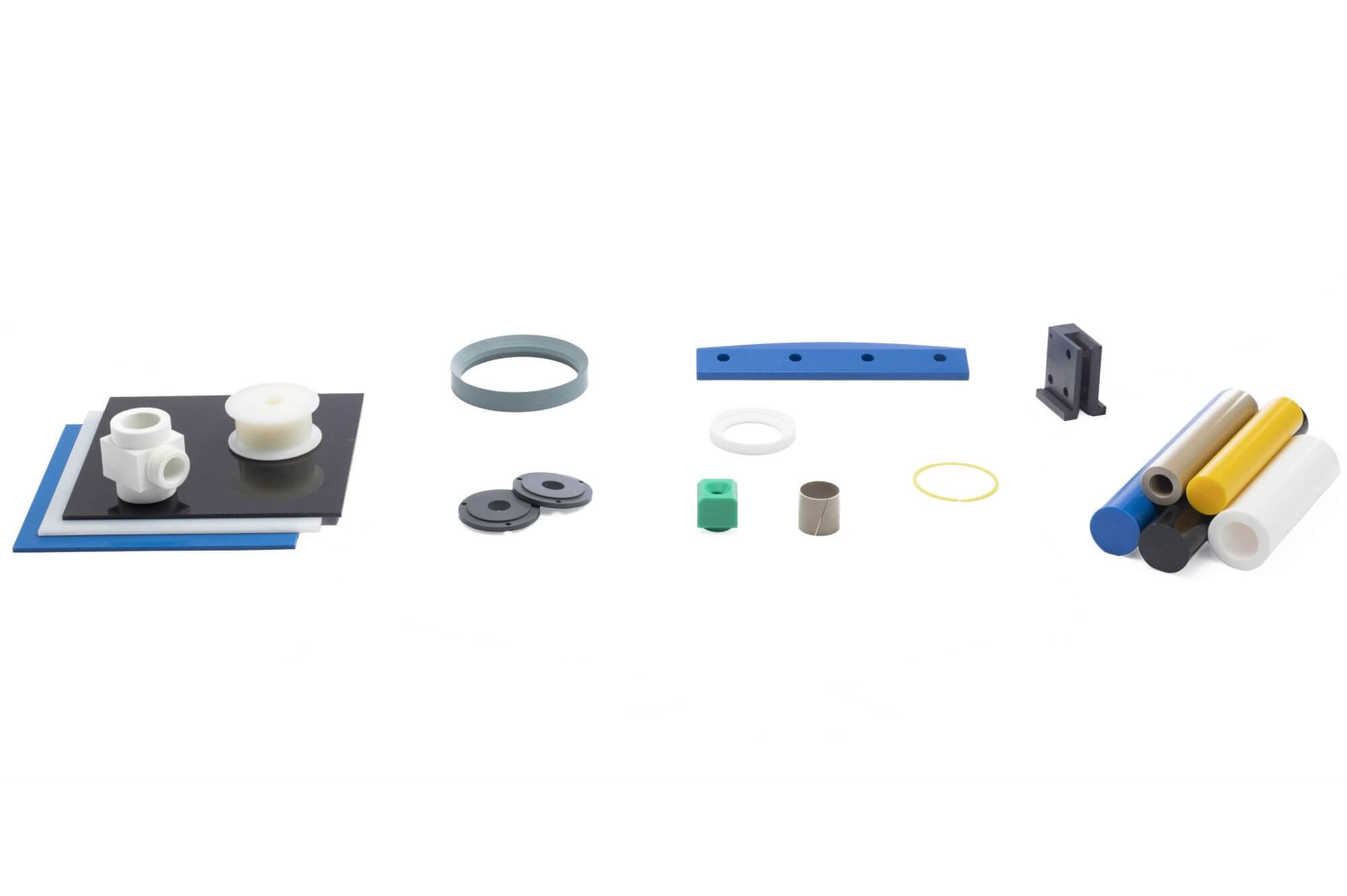

Water jet cutting is the ideal technology to manufacture your product from rubber, sponge rubber and plastic sheeting material to the most exact dimensions. Water jet cutting is a service provided by Ridderflex.

The advantages of water jet cutting:

- This is a cool cutting technique which is highly suitable for plastics.

- Since no heat is introduced into the material, its properties remain unchanged.

- The material does not deform or discolour.

- The cut is consistent and of a high quality (virtually free from burrs).

Water jet cutting rubber and foam rubber

We can water jet cut virtually all types of rubber of thicknesses up to approximately 200 mm. Also reinforced rubber (with inlays) and self-adhesive rubber can be water jet cut. Examples of rubber parts are transport rolls (for fruit and vegetables transport) and gaskets.

Water jet cutting plastics

We can water jet cut virtually all types of plastic of thicknesses up to approximately 200 mm. Also reinforced plastic (e.g. PTFE or TFM with additives) and self-adhesive foil can be water jet cut. Examples of plastic parts are gaskets and machine parts.

Question? Enquiry?

We excel in the production of custom-made plastic, rubber and polyurethane products.